Rolyan Synergy Thermoplastic Splinting Material

-

This product contains natural rubber latex which may cause allergic reactions.

-

For health reasons we are unable to accept returns or exchanges of hygiene products.

-

This item is considered dimensionally oversized parcel or requires truck delivery. Additional shipping charges will be calculated at time of order.

-

This item is classified as hazardous materials. Can ship ground only - restricted from air. Additional shipping surcharge will be added at time of order.

-

This product has a Bariatric rating.

-

If you have any questions please contact customer support at: 1.800.665.9200 or Email at:

customersupportca@performancehealth.com

OTHER ADDRESSES

| Company or Name | Street | Address 2 | City | Province | Postal |

|---|

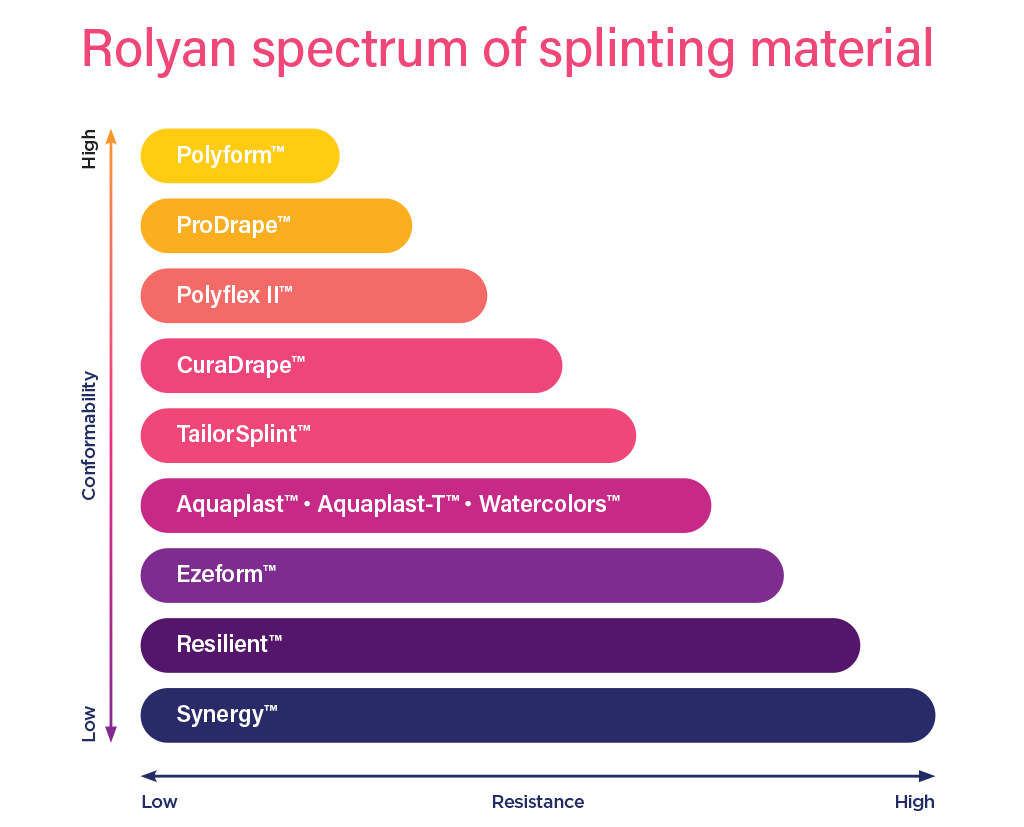

- Highest resistance to stretch and lowest conformability

- Splint is rigid and strong, ideal for medium and large splints

- Non-coated surface bonds instantly without preparation

- Minimal memory; but can be reheated and reshaped

- Non-toxic, latex-free, and radiolucent

Key Material Benefits

Synergy provides the highest molding control of any polycaprolactone-based Rolyan splinting material. It has a high resistance to stretch and minimum conformability and drape, giving the clinician full control of the fabrication.

Handling

Resistance to stretch: Maximum

Material does not stretch unless pushed or pulled in a direction and then held until cool. Unexpected patient movement will not cause the material to deform, and it does not stretch or deform when removed from splint bath.

Conformability: Minimum

Material does not conform to surface contours unless significant force is applied. Low degree of drape.

Memory: Minimum

Ability to be reheated and reshaped but will not return to original shape.

Bonding: Uncoated

Bonds permanently by pinching together heated surfaces.

Physical

Colors: Assorted

Blue or white

Thickness: 1/8" (3.2 mm) sheet thickness only

Perforations : Assorted

Available in 1 percent and solid material.

Appearance: Opaque when heated

Hardened Splint

Rigidity: Moderate/Maximum (57.6 kpsi*)

Retains shape without reinforcement.

Surface: Smooth

No unwanted fingerprints or markings.

*Refers to Young’s Modulus testing value

Learn More about Rolyan Hand Therapy

| Brand | Rolyan |

|---|---|

| Performance Preferred | Yes |

- Highest resistance to stretch and lowest conformability

- Splint is rigid and strong, ideal for medium and large splints

- Non-coated surface bonds instantly without preparation

- Minimal memory; but can be reheated and reshaped

- Non-toxic, latex-free, and radiolucent

US

US France

France Australia

Australia